| |

Ben

Heckendorn's NES Micro |

|

NEW FEATURE! Click to Enlarge -

click photos with this to open a really big full-pixel version

in a new window. Lets you check out detail and stuff.

Sometimes my creations have elaborate origins, like

"I've been

working on the idea for 15 years" or it came to me one day in the

bathroom. (Bathrooms and cars being places where I have most of my

best "idea bursts") But I'm sorry to say the NES Micro had no such "stroke of

inspiration" behind it. Rather I just had an extra NOAC (NES-on-a-chip)

Asian joystick game laying around and

figured I may as well do something cool with it instead of letting

it collect dust.

You may recall

that last year

(2004) I also cobbled together a NOAC portable, so the thing here

was to do something special. As many of you know I keep close track

of Nintendo's monthly Gameboy hardware releases so of course I knew of the

GBA Micro. Then it struck me - why not make an NES micro?

Ridiculously small screens and cramped controls shouldn't ONLY be

reserved for newer games! My path was set!

STEP 1 - Hacking up the NOAC board and converting

the connector

Most of those

cheap overseas NOAC game joystick things (or Super Fun Mecha

Joy-Joy Stick Fun units as I call them) have 60 pin Famicom

(Japanese) cartridge connectors on them. So as with my last NOAC

portable I had to hand-wire an adapter. The American NES has a

72-pin card edge connector.

This is a working NES clone, complete with

American 72-pin cartridge slot.

To keep it

small as possible I wired the adapter by hand, rather than using a

converter as with, say, a Game Axe, and kept the wires short. I used

2 old floppy drive cables for the cartridge slot. Don't call me

cheap (well I am, but) I just couldn't find the correct 72-pin

connector for the cartridge off Digi-Key. They're sort of obsolete

these days. You may notice a gap in

the center - this is fine as the center pins on a NES cartridge are

intended for the expansion slot on the bottom of the American NES.

Therefore they go unused. (No such extra cartridge pins were present

on the Famicom)

The NOAC, wired and plugged into a cartridge from

an era when Rare didn't take 5 years to make each game.

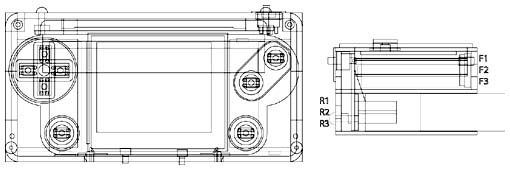

STEP 2 - Designing a really small case

Designing the case is always the hardest part for me, or at least

the most time consuming which I guess could be construed as the same

regardless. On top of the usual headaches and dial caliper marathons

was the fact I intended the NES micro to be as small as possible

and fit the following guidelines:

|

Not much

wider than a NES cartridge

|

|

Only a little

taller than an AA battery

|

|

Not much thicker

than a AA battery on top of a NES cartridge (.55" + .75")

|

|

As close to

the X Y width/height as a GBA Micro as possible. A GBA Micro is

4" x 2" on the X Y. I didn't worry about matching

the Z/depth as the NES cartridge is thick and makes that

impossible.

|

Lofty,

sure, but I figured I could handle it. In case you're just joining

us here on www.benheck.com here's the steps I take in designing one

of these things:

|

Boot up Adobe

Illustrator, get a Pepsi to drink

|

|

Measure all

the parts the portable requires. Typically cartridge, system

guts, screen size and batteries. Re-draw parts as vector

objects on computer.

|

|

Arrange parts

in a basic square that's the intended size of the unit. See

if it fits, if not increase square size. In this case I

started at 5" x 2.5" but ended up using 5.25" x 2.65"

|

|

Do side-angle

drawings to check the depth of the unit. Illustrator isn't

3D so I have to do this in various 2D drawings. (Autocad would be nice

to have but eating Ramen noodles for a year to afford it

wouldn't be)

|

|

Refine

drawing, put in screw-holes, decal positions, etc.

|

|

Make separate

versions of drawings for all individual parts to be laser

cut.

|

This unit has

a bit of a first as there's hinged battery doors. This was a space

issue, it was really the only thing I had room for. Even the buttons

were hollow so the tact switches could be INSIDE them rather than

under, saving space inside the unit for batteries:

Hollow buttons - an old trick from my

Vagabond 2000 days

STEP 3 - Cutting the case and assembling it

As with many of my more recent portables the parts for this were cut

out of Acrylic and engraving plastic using a laser engraver. This

allows for much smaller and more accurate parts than can typically

be had with a bit-based CNC router.

After the

parts are cut they are stacked and glued together. See, most of the

unit was made from 1/4" plastic, so the pieces get stacked to form

the actual case. By having different layers I can put various level

screw holes, spaces, etc inside the case.

Decals are

also printed (using a thermal vinyl printer) and attached to the

surfaces. This is a very important part of the process as it's

important for the thing to look good!

STEP 4 - Stuffing everything inside the case and

hoping it all fits (I mean... why

wouldn't it? ;)

And now comes the second hardest part of the whole process -

installing all the guts. See no matter how much planning I do in the

design phase there's always tons of monkeying around to get

everything to fit. I started with the controls, which basically

consists of tact switches under the buttons. The wiring is simple so

instead of having PCB's made (which would exceed the LCD screen in

expense!) I just do it by hand.

In the below

photo you can also see the 2.5" LCD screen has been installed. Most

of this stuff is secured with hot glue - yes I COULD screw

everything in place but if some slight discrepancy came along (which

they always do) then I'd be screwed! Hot glue at least allows...

"variance" (That's a fancy word to use so nobody notices me

slathering the stuff everywhere)

I ended up

using a 2.5" screen, a little bigger than a GBA Micro. And yes it

looks sharp, like the GBA Micro. But that's only because it's

smaller! Rule of graphics - anything look better smaller.

The front half of the case. With screen

and controls/control wiring installed. Note the battery doors swung

out at the bottom.

This next

photo shows how the batteries fit inside the case. The main design

"idea" was the case would be not much thicker than the screen or

batteries, and not much wider than them set side-by-side. This photo

is a good example of that. When building something like this the

biggest "things" are always 1) system guts 2) screen 3) battery and

4) game cartridge. Everything else, like power supplies and IC's for

audio amplification are all considered secondary (at least in my

book) That "extra stuff" can be fit anywhere!

Side/end view showing the vertical

layout of the parts. Batteries, screen and front portion.

For the

battery contacts I used the metal terminals from a pocket TV case

(Shocking I have several zillion of those laying around) The big

springs on the negative sides were cut down a bit to relieve the

pressure on the battery doors. Here you can see the NOAC has

been attached. Really all that hooks to it is +6 volts, ground,

Audio, Video and 3 wires for the controls.

The completed guts of the front side of

the case, sans volume knob and headphone jack. CLICK TO ENLARGE

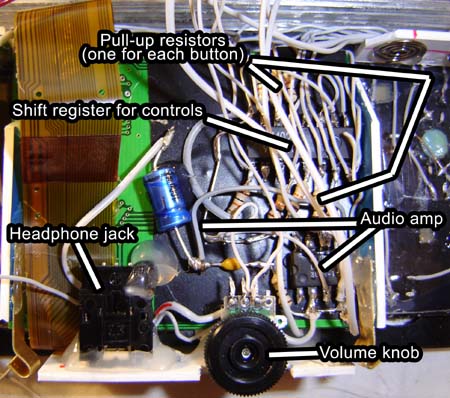

Here's a close-up detail of the hand-wired parts I put just

behind the screen. (This is the "extra stuff" mentioned a bit ago) A

NES controller is a bit more complex than say an Atari 2600 joystick

so the shift register IC and some pull-up resistors are required.

You can also make out the 386 audio amp, its capacitors and the

volume knob. Oh and the headphone jack. Note the overly long

LCD-to-controller board ribbon cable coming off the screen - that

thing was a pain!

Detail of the control/audio circuitry

inside the NES Micro

The NOAC guts

are then stuffed into the top of the unit as shown below. It sort of

holds the battery tabs in place (blue thing on middle left of photo)

It's packed so tight nothing is gonna go anywhere, believe me!

The unit with the NOAC board installed,

speaker wired and rear half of case ready for final assembly.

Finally the

rear half of the case is set over the front and screwed in place. I

put some nuts on the NOAC board, this allows screws to go through

the top of the rear half of the case and attach itself to the NOAC

board, as seen below. Since the cartridge will push and pull at that

point this is pretty much required for extra strength. Oh and you

can also see the power switch.

I thought

about coloring the case sides but thought it'd be cooler to leave it

transparent so a person can see inside. You know, to appreciate it

or something

End view showing the NOAC board and what

not

Here's some

assorted views of my NES Micro to look at:

Front view with game running. When the

batteries get weak (like 5 volts total) the screen gets a little

dimmer but still fine. Because of this normal alkalines, rather than

rechargeables, are best.

The speaker ended up on the lower left

hand side. Space was so tight this was the only place it'd fit. Oh

well. Chalk one up for weirdness.

View from the rear. Look - screw wells!

The first time I've ever used them, shocking I know!

And now finally, my

NES Micro compared to a GBA Micro....

NES Micro compared to GBA Micro (Micro

simulated as there's no way I'd buy one of those things)

OK so it's not AS

SMALL but considering it takes full size NES cartridges and was

built basically by hand I'd say I didn't do a bad job in shrink-a-fication.

Well that's about

all I have to say about my NES Micro. Don't worry, when Nintendo

releases their next "Gameboy Of The Year" in 2006 I'll be

sure to make some sort of comparison project then as well ;)

Back to www.benheck.com Homepage Back to www.benheck.com Homepage

|